PRODUCT CENTER

The company mainly deals in a wide range of steel products, including Angle steel, channel steel, H-beams, stainless steel plates, stainless steel coils, galvanized plates, galvanized coils, color-coated plates, color-coated coils, galvanized Angle steel, galvanized channel steel, galvanized flat steel and other products.

Color Coated Steel Coil for Household Appliances

Color Coated Galvalume Steel Coil PPGL

Production Experience

Active Employees

Floor Area

Exporting Countries

JUYUAN METAL MATERIALS CO., LTD.

Juyuan Metal Materials Co., Ltd. is adjacent to an important steel machinery industrial base in northern China. The company has many years of experience in industry exports and serves various customers in different industries. It is a leading enterprise specializing in the field of steel foreign trade, committed to providing high-quality steel products and one-stop supply chain solutions for global customers. It holds a prominent position in the global steel trading market.

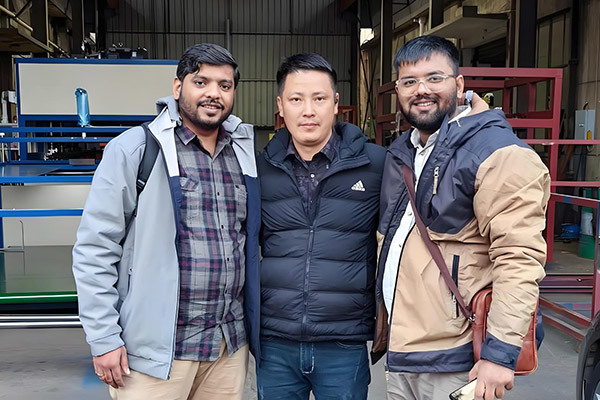

SEE MORE+CUSTOMER VISIT

Our products are exported to over 60 countries and regions in Southeast Asia, the Middle East, Africa, Europe and Latin America.

FACTORY VIDEO

Galvanized Steel Coil

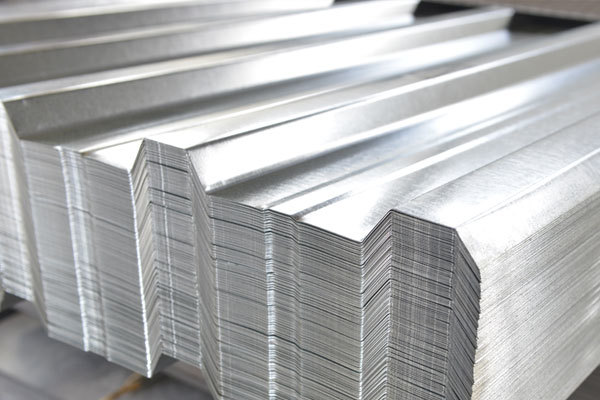

Galvanized Steel Sheet

Factory Production

FACTORY WORKSHOP

All products are strictly produced and inspected in accordance with international standards and customer requirements to ensure stable and reliable quality and outstanding performance.

BLOG

Galvanized Coil: Characteristics, Classification and Industrial Batch Application Analysis

Galvanized coil refers to a functional coiled material made from cold-rolled or hot-rolled steel coils, coated with zinc through continuous processes such as hot-dip galvanizing and electroplating, while maintaining its coiled form. Compared to single-sheet galvanized sheet, its coiled form allows for direct integration into downstream continuous production lines, enabling integrated uncoiling, shearing, stamping, and bending operations, significantly improving processing efficiency. It is a core raw material for mass production in industries such as home appliances, automobiles, and construction. From the continuous stamping of refrigerator side panels to the batch profiling of factory roof panels, all rely on it as a base material.

Galvanized Steel Sheet: Characteristics, Classification and Diverse Applications

Galvanized steel refers to cold-rolled or hot-rolled steel coated with a zinc layer through processes such as hot-dip galvanizing or electroplating. This zinc layer acts as a "cathodic protection" to isolate air and moisture from the steel, significantly improving its corrosion resistance while preserving the strength and workability of the base material. It is a leading corrosion protection material in industries such as industry, construction, and home appliances, finding widespread application in everything from automotive exteriors to building roofs, appliance panels, and municipal guardrails.

08-10

2025

Color-coated coils: characteristics, classification and industrial application analysis

Color-coated coil (full name: color-coated steel coil) is a functional roll-shaped material made from cold-rolled or galvanized steel coils. After surface pretreatments such as degreasing and phosphating, one or two layers of organic coating (such as polyester or fluorocarbon) are applied via a continuous roll-coating process, followed by high-temperature curing. Compared to single sheets of color-coated steel, its roll-shaped form is more compatible with downstream companies' continuous production lines, enabling efficient integration of cutting, stamping, and bending processes. It is a core raw material for mass production in industries such as construction, home appliances, and transportation. From factory roof panels to appliance housings, it serves as the base material for processing.

08-02

2025

Color-coated steel sheets: characteristics, classification and diverse applications

Color-coated steel sheets (also known as color-coated steel sheets) are functional sheets made from cold-rolled or galvanized steel sheets. After surface pretreatment (degreasing and phosphating), they are coated with one or more layers of organic coatings (such as polyester or fluorocarbon) via a roller coating process and then cured by baking. They combine the high strength of the base material with the decorative and corrosion-resistant coating, allowing for direct use without the need for subsequent painting. They are widely used to replace traditional painted steel sheets and ceramic tiles, becoming an ideal choice for "high-efficiency decoration and protection" in applications such as architecture, home appliances, and transportation.

07-21

2025

Stainless Steel Coil: Characteristics, Classification and Diverse Applications

Stainless steel coil is made from stainless steel billets containing at least 10.5% chromium. It is rolled through hot and cold rolling processes and then coiled into a strip-shaped profile. It combines the corrosion resistance and high strength of stainless steel. Its coiled form facilitates continuous processing and bulk shipping, making it a core raw material for downstream products such as sheet metal, pipes, and hardware. From small household appliance parts to large industrial equipment casings, it serves as a foundational substrate for processing.

07-11

2025

Stainless steel plates: core characteristics, classification and applications

Stainless steel is a type of alloy steel containing at least 10.5% chromium. Its dense chromium oxide passive film on its surface provides excellent corrosion resistance. Combined with its high strength, ease of processing, and attractive appearance, it has become an indispensable material in both industrial production and everyday life, found in everything from household kitchenware to large-scale industrial equipment.